Feed Mill Equipment in Small Rural Towns

How to build a low cost small animal feed mill factory in the countryside?

2020-11-02 Back to List

If you are looking for related products or have any other questions, please feel free to contact us.

Contact Us

With the continuous development of the breeding industry, many professional breeding households and professional villages have appeared in rural areas, which has increased the demand for feed. At the request of readers, today I will share with you some tips on how to build small animal feed mill factory plants in rural areas for your reference.

1. To conduct a feasibility analysis

The establishment of a small animal feed pellet line in a rural area must first conduct a thorough investigation, and then conduct economic analysis and technical demonstration on this basis. Only after the breeding industry needs, the economic benefits are good, the advanced feed production process and compounding technology is mastered, and the local spirit of "comprehensive planning, overall arrangement, adapting to local conditions, and reasonable layout" can be invested and built.

2. Scientifically determine the scale of small feed mill plant construction

The scale of small animal feed production is the basis for the design of animal feed pellet making plants. The scale of feed production should be determined according to the demand for feed in the supply area. The daily demand for feed can generally be calculated based on 0.15 kg per day for laying hens and 1.75 kg per day for pigs, and then the annual feed demand is calculated based on the total number of livestock and poultry raised in the supply area. Determine the production scale of the feed line for animals. For example, a small feed plant animal food manufacturing equipment with an annual output of 1,000 tons can raise 20,000 laying hens or 1,500 pigs.

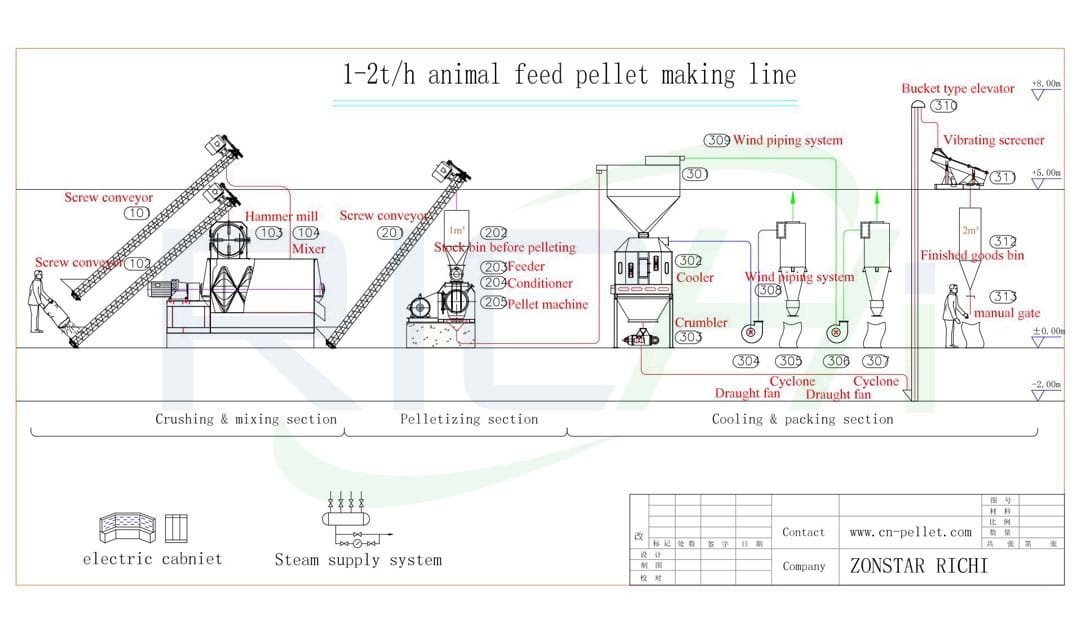

According to the local power supply situation, it should first be determined whether it is one-shift production or two-shift production. For example, for a compound feed mill factory with an annual output of 4,000 tons, if one-shift production is required, only equipment with a productivity of 2 ton-hours needs to be selected; if two-shift production, only feed processing equipment with an output of 1 ton/hour is selected. In order to give full play to the production capacity of the feed processing equipment. To improve economic efficiency, two-shift production is generally appropriate when the power is guaranteed.

In addition, the annual output base of the equipment, the prevailing saying in China is: if the equipment production output is 1 ton/hour, the annual production capacity is 2000 tons, this is a shift system, and the equipment annual time base is based on 2000 hours. Therefore, according to the feed production capacity of the animal feed equipment and further considering the development plan of the local aquaculture industry or the current aquaculture scale, the tonnage of the animal feed mill equipment can be selected according to local conditions, thereby scientifically determining the scale of the plant.

3. Choose the site correctly

The site of the animal feed processing machine plant should follow the principle of "processing nearby" and prioritize construction in townships with sufficient feed resources, developed animal husbandry, convenient transportation, guaranteed electricity, and markets, or villages with a certain scale of professional breeding households. If the small animal feed pellet production plant is built near the grain depot, or integrated with the grain depot, the housing facilities and corresponding costs for raw grain storage can be omitted.

Small poultry livestock feed pellet manufacturing plant for animal feed should not be built in toxic, harmful, pathogenic gas or dust-contaminated places, and should not be built near or under the limelight of livestock and poultry farms, pesticide factories, and sewage treatment plants.

4. How to choose small sized animal pellet feed mill machine?

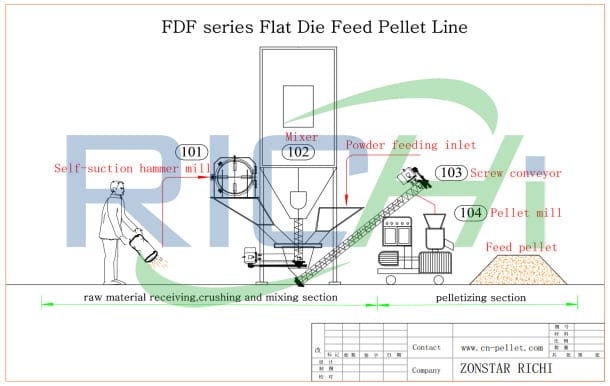

How to choose pellet feed press is a problem that every farmer cares about. Now take the small flat mode pellet machine as an example to talk about how to choose a pellet feed press.

(1) Choose different feed formulas according to the feeding objects. Such as fish, chicken, rabbit, sheep, etc. Among the pellets for fish and chicken, there are more concentrates. In the case of the same particle diameter, a thicker "mold plate" is generally used, rabbit and sheep pellets should use "thin" "die plates".This is because when there are more "precision" feeds, the suppression resistance is less and the power consumption is less. Generally, when using pellet feed for raising rabbits and sheep, the proportion of grass meal accounts for 50% or 60% of the total feed. When the grass meal is pressed and extruded in the "die plate" hole, the resistance is large, the power consumption is also large, and the electricity output is less than that of the pellets for fish and chicken.

(2) Choose according to the relevant standards of the Ministry of Agriculture. The hourly output of electricity should not be less than 40 kg (particle diameter 4 mm ~ 6 mm, referring to flat mode). When users choose, they should look at the label on the manufacturer's nameplate.

(3) The appearance of the pellets should be smooth, the hardness should be moderate, the crushing rate should be less than 4%, and the water content of the feed should be less than 10%.

(4) During the pressing process of animal pellet feed, the temperature of the pellets coming out of the machine should be about 60℃, which can be matured deeply, and should not exceed 80℃ at most, otherwise the various trace elements added in the pelleting process will be lost. Ensure the needs of livestock and poultry ingestion.

(5) It is best to choose an animal pellet feed making machine with "dry in, dry out", because the pellet feed produced by this machine does not require baking or exposure, and it can be bagged for feeding and storage after cooling to room temperature.

In addition, when choosing a small animal feed pellet mill machine for making pellets, you should choose products from regular and professional animal feed machinery manufacturers, and even shop around.

5. Choose Animal Feed Machine Production line Machine for Making Animal Food Carefully

Before setting up a plant for manufacturing animal feed, the corresponding complete set of feed pellet manufacturing plant equipment should be selected according to the determined production scale. The following issues should be considered when choosing:

(1) Selection of feed prodction process flow

Whether the animal feed pellet making plant process flow is reasonable or not is closely related to the investment, energy consumption, use and maintenance convenience of equipment and workshops.

As far as the material processing plant is concerned, the equipment strives for simplicity, which requires reasonable, simple and applicable process selection. In rural areas, the following three forms are generally appropriate:

① Continuously measure in proportion-crush-mix;

② Batch measurement-crushing-mixing;

③ Crushing-batch measurement-mixing.

(2) Selection of unit measurement form

There are two types of measurement: volumetric measurement and gravimetric measurement. The advantage of volumetric metering is labor-saving, but it is not easy to change the formula; The weight measurement accuracy is high, and it is more convenient to change the formula. Therefore, it is more accurate and convenient to measure by manual weighing in general small sized feed processing plants.

(3) Selection of feed processing line plant

The unit suitable for rural small plant pellet productions should have the following characteristics:

①The formula is easy to change, the proportioning is accurate, the mixing uniformity is good, and the feed particle size is adjustable.

②The unit has reasonable manufacturing process, simple structure, convenient operation, easy maintenance, compact overall layout and small floor space.

③Low noise and dust, and the unit must have safety control devices.

④Low energy consumption, low price, and easy to buy accessories.

At present, the small scale farm animal feed pelletizing line plants generally established in rural areas are mainly composed of small animal feed grinders and mixers, and basically all use manual weighing and measurement.

In summary, for feedstuff units with the same productivity, technical and economic indicators should be compared from the aspects of installed capacity, batching measurement method, power consumption, equipment price, and required plant area, and comprehensive analysis should be performed to select them. The required production line equipment. Generally speaking, to establish small feed processing plants in rural areas, a complete set feed producing equipment with an output of 400kg/h to 2000 kg/hour should be selected.

6. Correct use of corn grinder for animal feed

(1) The small animal feed grinder should be fixed on the cement foundation for long-term operation. If the working location is frequently changed, the grinder and the motor should be installed on the frame made of angle iron. If the grinder is powered by a diesel engine, the power of the two should be matched, that is, the power of the diesel engine is slightly greater than that of the pulverizer, and the pulley grooves of the two are consistent, and the outer end surface of the pulley is on the same plane.

(2) After the feed hammer mill grinder is installed, check the fastening of each part of the fasteners, and tighten them if they are loose.

(3) Check whether the belt tightness is appropriate and whether the motor shaft and the shredder shaft are parallel.

(4) Before starting the small animal feed crusher machine for grinding feed powder, turn the rotor by hand to check whether the claws, hammers and the rotor are running flexibly and reliably, whether there is any collision in the shell, and whether the rotation direction of the rotor is consistent with the direction indicated by the arrow on the machine. Whether the grinder is well lubricated.

(5) Do not change the belt pulley casually, in case the speed is too high and the crushing chamber explodes, or the speed is too low to affect the work efficiency.

(6) After starting, the grinder will run idling for 2 to 3 minutes, and then feed the material after there is no abnormal phenomenon.

(7) Pay attention to the operation of the crusher at all times during work, and feed evenly to prevent blocking the car, and do not overload it for a long time. If there are vibrations, noises, excessive temperature of the bearing and the body, or spraying materials, you should stop and check immediately, and then continue to work after troubleshooting.

(8) The crushed materials should be carefully checked to avoid accidents caused by hard objects such as copper, iron, and stones entering the crushing room.

(9) Operators should not wear gloves, stand on the side of the grinder when feeding, to prevent rebound debris from hurting the face.

(10) When it is blocked, it is strictly forbidden to forcibly feed or drag out feed by hand or wooden stick.

7. Forage Crusher

The grass shredder machine is mainly used to crush various kinds of hay and crop straws and other coarse fodder. Farms, pastures and breeding professionals use it to process grass meal fodder. The forage grinder can be matched with the pelletizer and other equipment to form a coarse feed processing unit with grass or straw as the main raw material. Can produce powder feed or pellet feed. Pellet feed is not easy to deteriorate, is easy to transport and store, and has strong palatability. It is the best feed for ruminants such as cattle, sheep, camels and poultry. If the moisture content of the raw material is below 15% and the sieve opening is 3 mm (such as the size of sorghum grains), it can produce more than 500 kg per hour. The annual output of a single shift can reach more than 1,000 tons, and the economic benefits are considerable.

(1) Precautions and usage methods

Before use, check the electrical equipment for leakage, whether the bolts in each part are loose, whether the hammer and screen are damaged, and the air regulating plate should be halfway open or fully open state. Start the dry wet grass hammer mill and run it empty for 10 to 15 minutes before it can be used. Tighten the cuffs, put on a work cap, stand on both sides of the feed inlet, and pick out hard debris such as broken bricks and tiles in the material. Don't extend your arm into the filling chamber, and don't use iron rods to poke the material. The material should be evenly fed. Don't leave casually, let alone put tools and other things on the stockpile. When you need to check the inside of the grain grass hammer mill, cut off the power first. After the work is done, turn it off the switch to clean the site.

(2) Repair and maintenance

Pay attention to inject grease into the rotor bearing of the straw shredder hammer mill at any time. When the grinder has been working for about 500 hours, the rotor bearing of the grinder should be cleaned and an appropriate amount of butter should be injected. The hammer is the only vulnerable part of the machine. The angle of the hammer can be changed according to the degree until it is completely unusable. All the new hammers must be replaced at one time to ensure that the original balance is staggered to achieve a balanced state under high-speed operation and prolong the service life of the stalk hammer mill. If the sieve is small, it can be used after repair. If the machine is not used for a long time, clean up all parts and pay attention to moisture and rust prevention.

rutledgethowithid.blogspot.com

Source: https://www.cn-pellet.com/faq/1156.html

0 Response to "Feed Mill Equipment in Small Rural Towns"

ارسال یک نظر